Investment secures BMW's long-term future at Hams Hall

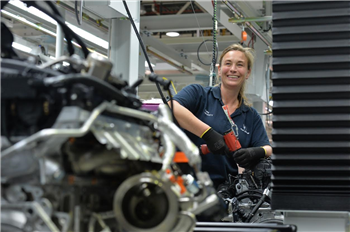

A huge investment programme to develop the BMW engine plant at Hams Hall near Coleshill is complete.

A huge investment programme to develop the BMW engine plant at Hams Hall near Coleshill is complete.

The investment project, part of £750 million spent by the BMW Group across its UK manufacturing sites, has secured the long-term future for the Hams Hall plant by ensuring the site remains a state-of-the-art facility capable of producing the next generation of engines.

The production of new three and four-cylinder engines is already being ramped up on brand-new production lines and over one million components will be machined at the plant for the first time this year as supply extends to other plants in the group.

Engines, as well as machined components manufactured at BMW Plant Hams Hall, contribute to a range of cars across BMW Group’s product portfolio. This includes MINI – the new Clubman model, as well as the new BMW 7 Series.

Plant director Markus Fallboehmer said: “The transformation in our Hams Hall plant has been huge. Over the last few years we have completely redeveloped our two main production areas and installed over 600 brand new pieces of equipment and machinery.

“A large investment has also been made in our workforce via a number of training programmes and opportunities for people to upskill and take on new job roles.

"We have changed the make-up of our workforce as well with over 100 people securing BMW contracts, some of whom were previously working for us on a temporary basis."

BMW's success and continuing expansion at Hams Hall is excellent news for north Warwickshire on the employment front with the company fully sharing Warwickshire County Council's commitment to taking on apprentices.

"We have trebled the number of apprentices training with us to ensure we have a strong, skilled workforce for many years to come,” said Mr Fallboehmer.